Silica is found in many minerals common on construction sites, including sand, granite, concrete, brick and most other types of rock. When workers cut, grind, abrasive blast, jackhammer or perform other tasks that disturb these materials, dust containing crystalline silica can be released into the air. Workers who inhale this dust are at risk.

The Occupational Safety and Health Administration (OSHA) has now issued a Final Rule to help combat lung cancer, silicosis, chronic obstructive pulmonary disease, and kidney disease within America’s workforce by implementing a new section to the silica standard limiting exposure to crystalline silica dust.

The Final Rule for construction employers will take effect June 23rd, 2017 with an enforcement date of Sept 23, 2017.. This is when all construction employers must be in full compliance with the new OSHA ruling.

Standard Requirements:

The OSHA standard for crystalline silica dust requires employers to limit worker exposure and take further steps to ensure the safety of their workforce. Due to the new updates, employers can either use a control method that is explained in Table 1 (see Table 1 below) of the construction standard, or they can measure workers exposure independently and further determine which safety measures will be taken.

Whichever method is chosen, all construction employers are required to:

- Establish and implement a written exposure control plan that identifies tasks that involve exposure and methods used to protect workers, including procedures to restrict access to work areas where high exposures may occur.

- Designate a competent person to implement the written exposure control plan.

- Restrict housekeeping practices that expose workers to silica where feasible alternatives are available. You must use floor sweep every time you sweep.

- Offer medical exams – including chest X-rays and lung function tests – every three years for workers who are required by the standard to wear a respirator for 30 or more days per year.

- Train workers on work operations that result in silica exposure and ways to limit exposure. For example; Use wet methods when feasible and if conditions permit

- Keep records of workers’ silica exposure and medical exams.

What is Table 1?

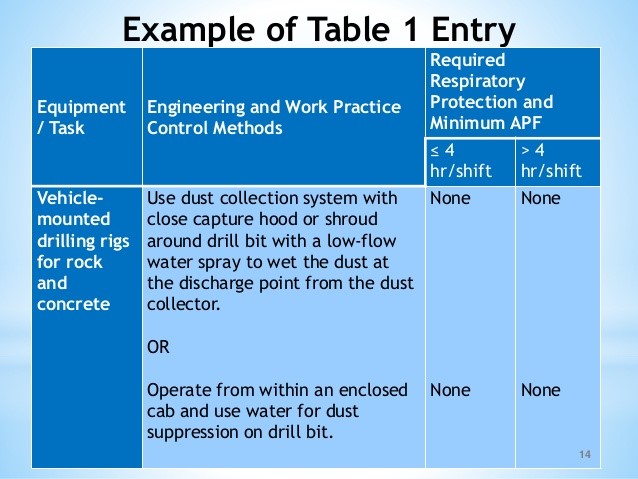

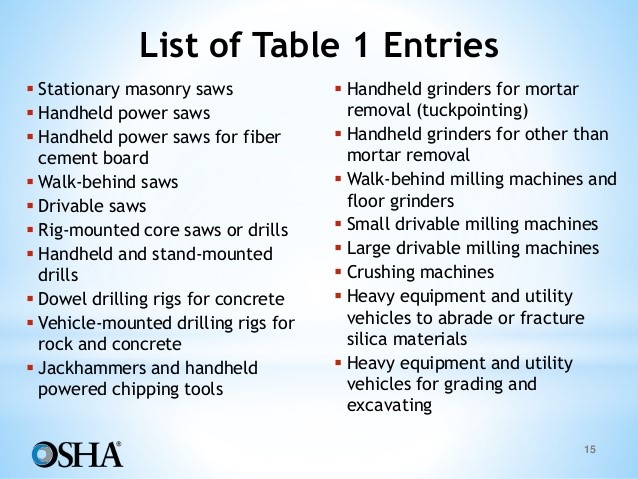

Table 1 describes certain construction tasks and matches them with dust control methods so that employers know what steps need to be taken to limit employee exposure to respirable crystalline silica dust. The dust control measures listed in the table include methods know to be effective, like using water to keep dust from getting into the air or using ventilation to capture the dust. Although methods listed in the table give examples for how to reduce respirable dust, respirators may still need to be used.

We will be using Table 1 as our method of control. You must use dustless tools when drilling, cutting , hammering into an material that contains silica. The safety department will be coming around to each site to do Silica Awareness Training in the coming days/weeks.